功能性委員會

審計委員會

薪資報酬委員會

永續發展暨風險管理委員會

目的及職權

■ 本公司審計委員會每季應至少召開一次會議,並得視需要隨時召開會議。

1. 本公司審計委員會之運作,以下列事項之監督為主要目的:

1-1 公司財務報表之允當表達。

1-2 簽證會計師之選(解)任及其獨立性與績效。

1-3 公司內部控制之有效實施。

1-4 公司對相關法令及規則之遵循。

1-5 公司存在或潛在風險之管控。

2. 本公司審計委員會之職權事項如下:

2-1 依證交法第十四條之一規定,訂定或修正內部控制制度。

2-2 內部控制制度有效性之考核。。

2-3 依證交法第三十六條之一規定,訂定或修正取得或處分資產、從事衍生性商品交易、資金貸與他人、為他人背書或提供保證之重大財務業務行為之處理程序。

2-4 涉及董事自身利害關係之事項。

2-5 重大資產或衍生性商品交易。

2-6 重大資金貸與、背書或提供保證。

2-7 募集、發行或私募具有股權性質之有價證券。

2-8 簽證會計師之委任、解任或報酬。

2-9 財務、會計或內部稽核主管之任免。

2-10 由董事長、經理人及會計主管簽名或蓋章之年度財務報告。

2-11 營業報告書、盈餘分派或虧損撥補之議案。

2-12 其他公司或主管機關規定之重大事項。

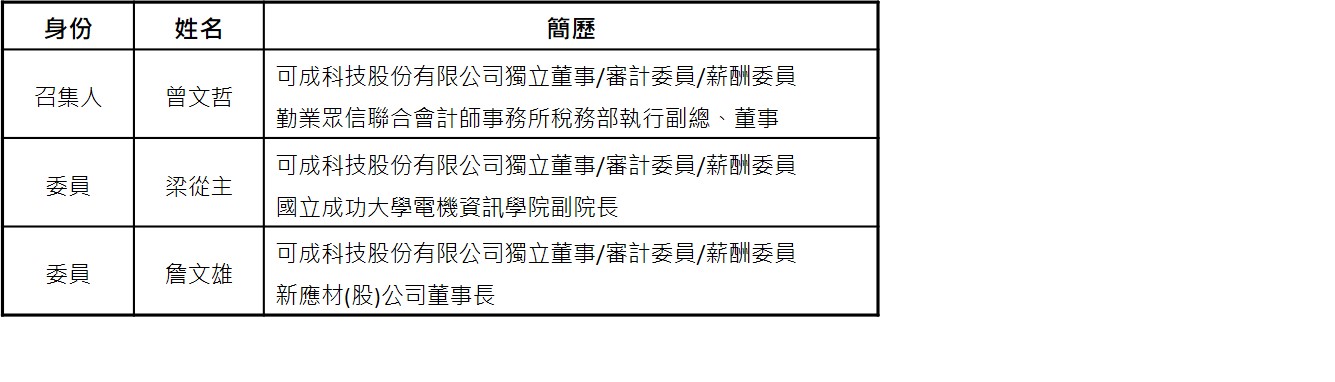

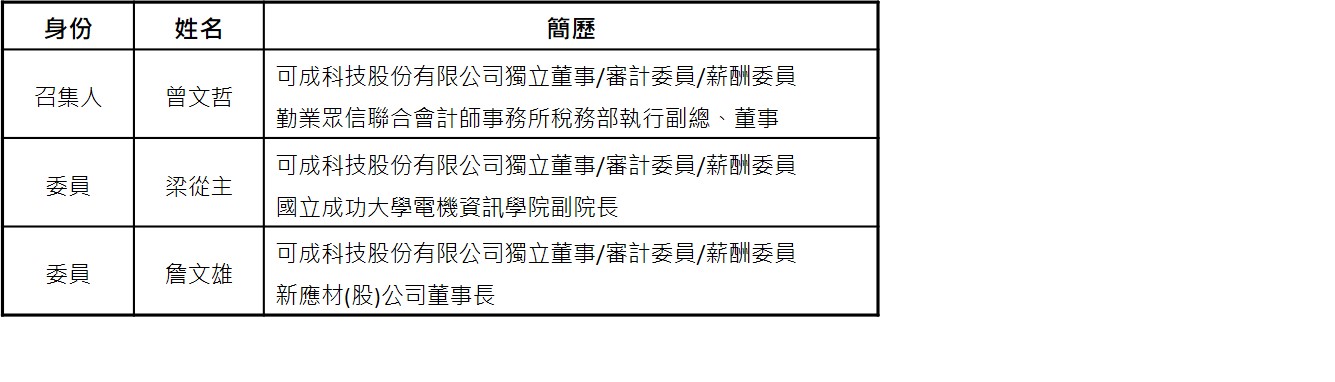

審計委員會成員

本公司之審計委員會委員計3人,全體由獨立董事組成。

審計委員會年度工作重點

本公司審計委員會委員共計3人,全體由獨立董事組成,每季定期於董事會前召開會議檢視公司內控制度與內部稽核之執行,以及重大財務業務行為,並與簽證會計師溝通及交流,以確實監督公司運作與風險控管。

114年度本公司審計委員會共計召開5次會議,主要審議事項如下:

■ 審閱各季財務報告

■ 訂定或修訂內部控制制度暨相關辦法

■ 內部控制制度有效性考核

■ 資產取得及資金貸與交易

■ 審閱營業報告書、盈餘分派之議案

■ 評估簽證會計師獨立性及會計師事務所審計品質指標

■ 審議金融機構授信額度

審計委員會出席情形

114年度審計委員會

*詹文雄董事於114.05.27新任本公司審計委員,114年度應出席2次會議。

委員

實際出席次數

委託出席次數

出席比率

曾文哲

5

0

100%

梁從主

5

0

100%

詹文雄

2

0

100%

審計委員會會議資訊

114年度本公司審計委員會召開會議重點如下:

日期

議案

決議

24 Feb 2025

- 113年度合併及個體財務報表

- 113年度營業報告書

- 113年「內部控制制度聲明書」

- 修訂「公司章程」部份條文

- 定期評估「簽證會計師獨立性」

- 定期評估「會計師事務所審計品質指標」

- 擬訂「提供非確信服務之預先核准審核辦法」

- 貸與資金予越南子公司以因應其營運需求

- 追認向關係人取得供營業使用之設備

- 其他會計審計議題

委員會全體成員同意通過,已依主管機關規定公告

16 Apr 2025

- 113年下半年度盈餘分派案

- 解除新選任董事及其代表人競業禁止限制案

委員會全體成員同意通過,已依主管機關規定公告

09 May 2025

- 114年第1季合併財務報告案

- 追認向關係人取得供營業使用之設備

委員會全體成員同意通過,已依主管機關規定公告

08 Aug 2025

- 114年第2季合併財務報告案

- 就本公司自為背書之關稅保證額度新臺幣壹仟萬元,申請辦理展延

- 其他會計審計議題

委員會全體成員同意通過,已依主管機關規定公告

06 Nov 2025

- 本公司114年上半年度營業報告書

- 本公司114年上半年度盈餘分派案

- 本公司114年第3季合併財務報告案

- 擬修訂本公司內部控制制度

- 貸與資金予泰國子公司Topo Technology (Thailand) Co., Ltd.以因應其營運需求

- 追認向關係人取得供營業使用之設備

委員會全體成員同意通過,已依主管機關規定公告

目的:定期檢討薪資報酬

■ 本公司薪資報酬委員會每年應至少召開2次會議。

■ 本委員會之職能,係以其專業客觀地位,對本公司董事及經理人之薪資報酬政策及制度予以評估,並向董事會提出建議,以供其決策參考。

1. 薪資報酬委員會職權

本委員會應以善良管理人之注意,忠實履行下列職權,並將所提建議提交董事會討論:

1-1 訂定並定期檢討本公司董事及經理人績效評估與薪資報酬之政策、制度、標準以及結構。

1-2 定期評估並訂定董事及經理人之薪資報酬。

2. 薪資報酬委員會履行職權,應依下列標準為之:

2-1 確保公司之薪資報酬安排符合相關法令並足以吸引優秀人才。

2-2 董事及經理人之績效評估及薪資報酬,應參考同業通常水準支給情形,並考量與個人所投入之時間、所擔負之職責、擔任其他職位表現、公司近年給予同等職位者之薪資報酬,以及由公司短期及長期業務目標之達成、公司財務狀況等評估個人表現與公司經營績效及未來風險之關連合理性。

2-3 不應引導董事及經理人為追求薪資報酬而從事逾越公司風險胃納之行為。

2-4 針對董事及高階經理人短期績效發放紅利之比例及部份變動薪資報酬支付時間,應考量行業特性及公司業務性質予以決定。

2-5 本委員會對於會議討論其成員之薪資報酬事項,應於當次會議說明,如有害公司利益之虞時,該成員不得加入討論及表決,且討論及表決時應予迴避,並不得代理其他委員會成員行使其表決權。

薪資報酬委員會成員

本公司薪資報酬委員會委員計3人,全體由獨立董事組成。

薪資報酬委員會年度工作重點

本公司薪資報酬委員共計3人,全體由獨立董事組成,每年至少召開2次會議,主要工作重點包含檢視公司薪資報酬政策與董事、經理人薪酬,確保公司薪酬架構之合理性與市場競爭力。

114年度本公司薪資報酬委員會共計召開3次會議,主要審議事項如下:

■ 訂定並定期檢討董事及經理人績效評估與薪資報酬之政策、制度、標準與結構。

■ 定期評估並訂定董事及經理人之薪資報酬。

薪資報酬委員出席情形

114年度薪資報酬委員會

114年度本公司薪資報酬委員會共計召開3次會議,3位獨立董事出席情形如下:

*詹文雄董事於114.05.27新任本公司薪資報酬委員,114年度應出席2次會議。

委員

實際出席次數

委託出席次數

出席比率

曾文哲

3

0

100%

梁從主

3

0

100%

詹文雄

2

0

100%

薪資報酬委員會會議資訊

114年度本公司薪資報酬委員會召開會議重點如下:

日期

議案

決議

24 Feb 2025

- 評估本公司董事及經理人之酬金、薪資給付及結構

- 審查本公司113年度員工及董事酬勞提撥計畫

- 董事、董事會暨功能性委員會績效評估結果

委員會全體成員同意通過 已依規定提報董事會

08 Aug 2025

- 發放113年度董事酬勞

- 發放113年度經理人之員工酬勞

委員會全體成員同意通過 已依規定提報董事會

目的及職權

■ 本公司永續發展暨風險管理委員會每年應至少召開1次會議,並得視需要隨時召開。

■ 本委員會依董事會授權,應本於善良管理人之注意義務,忠實履行下列職權,並適時提報董事會審議:

1. 制定、推動與強化永續發展方向,包含氣候變遷與環境保護、社會及人權議題、公司治理暨風險控管等議題,並擬定目標及推動策略。

2. 追蹤、檢視永續發展執行情形。

3. 督導永續資訊揭露事項,提升永續資訊的準確性及透明度。

4. 督導經董事會決議之永續發展相關工作之執行。

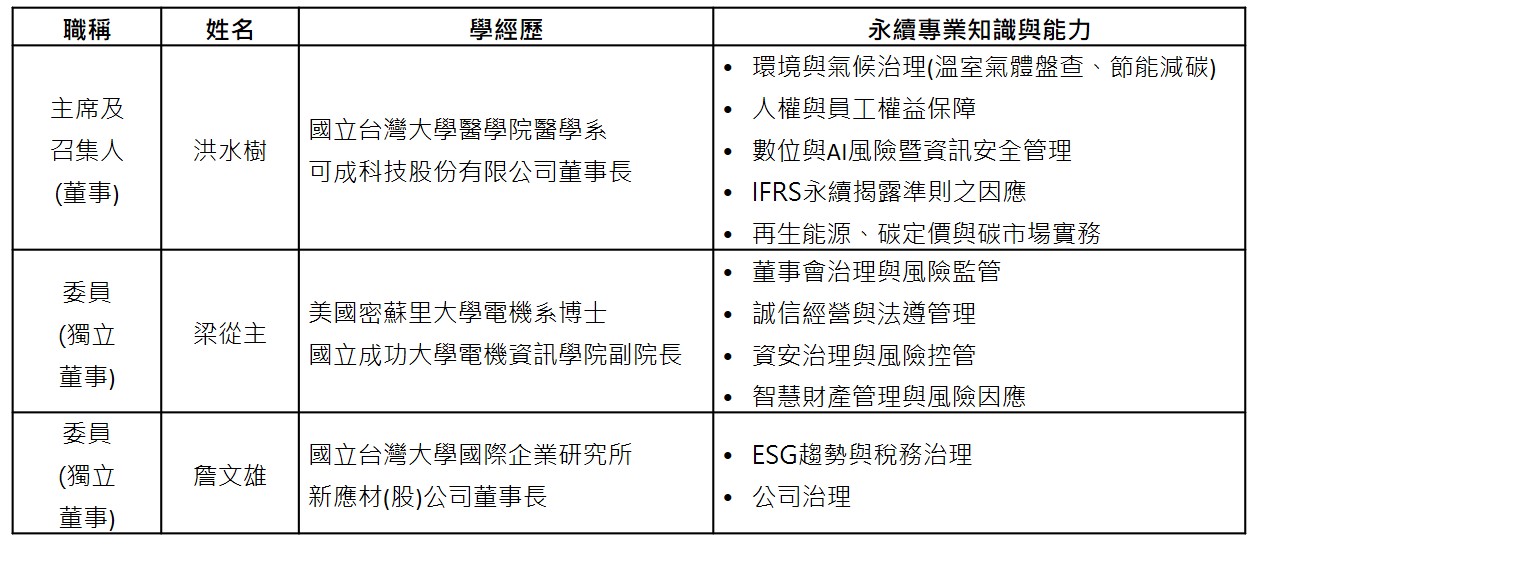

永續發展暨風險管理委員會成員

本屆委員會成員共計3人,由董事長及2位獨立董事組成,任期自2025年11月06日起至2028年5月26日止。所有成員皆具備風險管理、危機處理及永續相關專業知識與能力。

永續發展暨風險管理委員會出席情形

2025年永續發展暨風險管理委員會出席情形

依據「可成科技股份有限公司永續發展暨風險管理委員會組織規程」,本公司永續發展暨風險管理委員會每年應至少召開1次會議;2025年共計開會1次,3位委員出席情形如下:

委員

實際出席次數

委託出席次數

出席比率

洪水樹

1

0

100%

梁從主

1

0

100%

詹文雄

1

0

100%

永續發展暨風險管理委員會會議資訊

2025年本公司永續發展暨風險管理委員會召開會議重點如下:

日期

議案

決議

30 Dec 2025

- 推舉本公司永續發展暨風險管理委員會召集人

- 訂定本公司「永續發展實務守則」

- 2025年企業永續發展暨風險管理執行情形與未來目標

委員會全體成員推選洪水樹委員擔任召集人;議案經委員會全體成員同意通過,並提請董事會決議

站內搜尋

Start typing keywords to discover the service, support, or details you’re looking for.

隱私權政策

歡迎來到「可成網站」(以下稱「本網站」)。為了讓您安心使用本網站的各項服務與資訊,特此向您說明本網站的隱私權政策,以保障您的權益,請詳閱下列內容:

01. 隱私權政策適用範圍

本政策適用於您使用本網站服務時所涉及的個人資料蒐集、處理與利用方式。但不適用於本網站所連結之其他網站,也不適用於非本網站所委託或管理之人員。

02. 個人資料的蒐集、處理與利用方式

當您造訪或使用本網站服務時,可能依服務性質請您提供必要的個人資料,且僅於特定目的範圍內處理與利用,未經您的書面同意,不會另作他用。 使用如聯絡表單、留言或問卷等互動功能時,本網站可能會保留您的姓名、電子郵件、聯絡方式及使用時間。一般瀏覽時,伺服器會自動記錄您的 IP 位址、使用時間、瀏覽器類型、瀏覽紀錄等資訊,作為改善網站服務之用,不對外揭露。 為提供更精準的服務,本網站可能對問卷內容進行統計分析,統計結果可能以數據或文字呈現供內部研究或對外公開,但不包含個人身分資訊。

03. 資料保護

本網站的伺服器均設有防火牆、防毒系統及其他相關資安設備,以確保您的個人資料受到妥善保護。僅限經授權人員得以接觸資料,所有相關人員皆已簽署保密協議,違者將依法處理。 如因業務需要委外處理個人資料,本網站將充分監督並要求其確實遵守保密義務。

04. 外部連結

本網站可能提供外部網站連結,但本網站的隱私權政策並不適用於該等網站。請您自行參閱各該網站的隱私權政策。

05. 個人資料之第三方共享

本網站絕不會出售、交換、出租或提供您的個人資料予任何個人、公司或機關,但符合法律或契約義務之情形除外。

例外情形包括但不限於:

01. 經您書面同意

02. 法律明文規定

03. 為防止危及您的生命、身體、自由、財產之危險

04. 為公共利益,與政府或學術機構合作進行統計或學術研究(資料經處理後無法識別個人)

05. 您在本網站之行為違反服務條款,或造成其他使用者或第三人損害

06. 為維護您的權益

07. 委外機構協助蒐集、處理或利用個人資料,且本網站依法監督其行為

06. Cookie 之使用

為提供更佳服務,本網站將於您的裝置上寫入並讀取 Cookie。若您不願接受,可透過瀏覽器設定提高隱私權等級,但可能導致部分功能無法正常運作。

07. 隱私權政策修訂

本政策將因應需求隨時修訂,修改後的條款將公布於本網站。