Certification

Lab & Equipment

Process Control

Quality Culture

Partnership

World-Class Quality Management System

Key performance metrics tracked in real time: Customer Satisfaction, Reject Rate (<0.01%), Scratch Rate (<0.005%) and HSF compliance

Quality Control Design

Our engineering expertise allows us to build inspection systems that are simple, effective, and scalable — knowing what, when, and how to inspect to achieve optimal quality performance and cost efficiency.

ISO 9001 : 2015

Embedded within our ISO 9001:2015 quality management system, we integrate process development, manufacturing management, inspection, calibration, numerical analysis, nonconformity handling, and lessons learned into a unified platform. Automated Closed-Loop Corrective Action (CLCA) workflows ensure real-time alerts, root-cause analysis, and continuous, cross-functional improvement.

Download

ISO 13485 - Medical Devices

Certified in developing and manufacturing precision medical device and components.

This certification ensures that every stage — from design and development to production and traceability — complies with stringent global regulatory standards, helping customers streamline audits and reduce compliance risks.

AS9100 - Aerospace and Defense Industries

We meet the world’s most demanding aerospace and defense standards through precision machining, full traceability, and disciplined process control — ensuring every component performs with reliability and consistency.

Other Certifications

ISO 27001

Information Security

ISO 45001

Occupational Health & Safety

IATF 16949

Automotive

ISO 14001

Environment

ISO 27001

Information Security

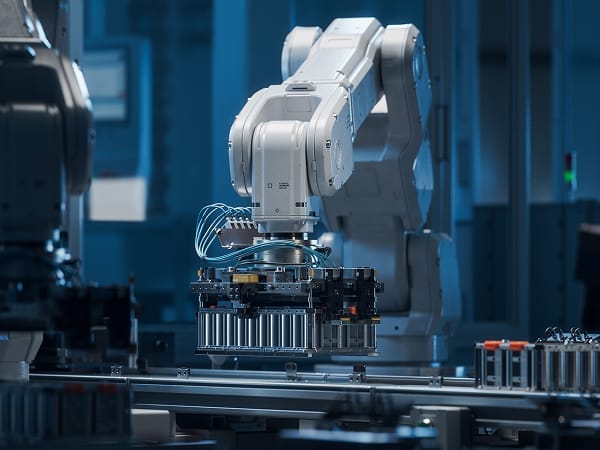

Inspection & Testing Laboratories

From defect detection to process innovation, our advanced inspection systems empower Catcher to deliver flawless precision — faster, smarter, and more reliably.

Dimensional Metrology

Coordinate-Measuring Machines (CMM) and optical/vision systems for ±1 µm accuracy

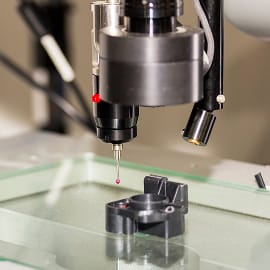

Contact Measurement Machine

Measures product dimensions using a contact probe, suitable for high-precision geometric inspection.

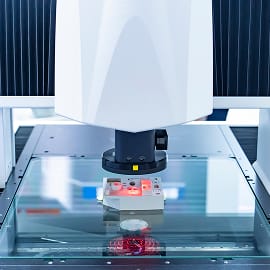

Vision Comparison Measuring System

Captures images to measure product dimensions; allows direct, rapid dimension marking and comparison with original CAD drawings.

Optical Measurement Machine

Utilizes non-contact optical measurement with high-precision linear scales, probes, and controllers to ensure measurement accuracy and system stability.

Cosmetic Inspection

Hardness testers, cross-hatch adhesion, gloss/chromaticity and surface-roughness measurement

Colorimeter

Measures color parameters (L, a, b) of materials for color deviation detection and color difference analysis.

Scanning Electron Microscope (SEM)

Uses a focused electron beam to scan the sample surface, producing high-magnification images via secondary or backscattered electrons. Allows on-image distance measurement and digital imaging. When combined with EDS (Energy Dispersive X-ray Spectroscopy), elemental analysis is also possible.

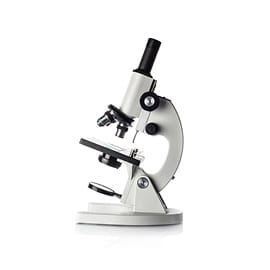

Optical Microscope

Uses visible light and optical lenses to magnify sample surfaces. Equipped with imaging software and digital cameras for on-screen measurements and image capture.

Surface Treatment Reliability Lab

ICP-OES, GC-MS, XRF and UV-Vis spectrometry to verify alloy composition and coating integrity

ICP-OES

Uses plasma to excite elements in the sample, causing them to emit light at characteristic wavelengths. The emitted light is then dispersed by an optical system, allowing for qualitative and quantitative analysis based on each element’s unique spectral lines.

GC-MS

Separates mixtures through gas chromatography, then analyzes the vaporized components with mass spectrometry to obtain molecular structure information.

UV-Vis

Employs ultraviolet or visible light lamps as a light source; through filters and dispersion, a specific single wavelength is directed onto the sample. By comparing the light energy absorption to a standard sample, the concentration of the analyte is determined.

XRF

Irradiates the sample with X-rays, causing inner-shell electrons of elements to absorb energy and emit characteristic X-rays as they return to the ground state. Different elements emit distinct X-ray signatures, enabling comprehensive elemental analysis of the sample.

FTIR

Infrared spectroscopy identifies materials based on how their molecules absorb infrared light at different wavelengths. FTIR uses mathematical conversion to transform raw interferograms into standard absorption spectra, allowing accurate analysis of material composition.

Statistical Process Control & Traceability

Data-driven oversight for consistent, predictable output

Real-Time SPC

Real-time Statistical Process Control (SPC) for key processes leverages measurement databases to monitor stability and variation, while advanced AI technologies extend this capability from product monitoring to proactive process parameter control.

Full Lot-Level Traceability

Our traceability system links raw materials to final shipment, recording every process parameter and inspection record. This transparency supports real-time analysis and continuous quality enhancement.

Relentless About Quality

We embed quality into every action — eliminating risk, elevating standards, and driving trust across everything we make.

Continuous Improvement

Beyond CLCA for nonconformities, we apply the PDCA cycle to manage risks and drive continuous improvement across all processes.

Turning Insight into Action

We review KPIs, feedback, and audit results weekly to turn insights into rapid improvement actions.

Quality Awareness Training

We train our teams on quality improvement tools and methods with our structured curriculum, and support growth through ASQ CQE and CSSBB certifications.

Partnering for Perfection

We view every customer as a co-engineer — uniting expertise and precision to achieve uncompromising quality.

Joint Quality Reviews & Audits

We work closely with customers to align our quality management system with their product specifications, regularly monitor progress toward their quality goals, and proactively propose optimization plans.

Certified Supplier Network

Every critical sub-supplier follows our rigorous onboarding standards and undergoes monthly quality performance reviews.

Start Your Project With Us

Feel free to contact Catcher Technology through the information below. We will respond to your inquiry as soon as possible.

Contact Us

OTHER CAPABILITIES

SEARCH

Start typing keywords to discover the service, support, or details you’re looking for.

PRIVACY POLICY

Welcome to the “Catcher Website” (hereinafter referred to as "this website"). To help you use our services and information with peace of mind, we hereby explain our privacy policy to safeguard your rights. Please read the following carefully

01. Scope of the Privacy Policy

This policy covers how this website handles personal information collected when you use its services. It does not apply to websites linked from this site, nor to personnel not managed or authorized by this website.

02. Collection, Processing, and Use of Personal Data

When you visit this website or use its services, we may ask you to provide necessary personal data depending on the nature of the service, and your data will be processed and used solely for that specific purpose. Without your written consent, your data will not be used for any other purposes. When using interactive features such as contact forms or surveys, this site may retain your name, email address, contact information, and usage time. During general browsing, the server will automatically record your IP address, usage time, browser type, and browsing data. This information is used internally to improve our services and will not be shared externally.To provide accurate services, we may conduct statistical analysis on collected survey data. The results may be published as statistical summaries or explanatory text for internal research or public reference, but they will not contain personally identifiable information.

03. Data Protection

The servers of this website are protected with firewalls, antivirus software, and other security measures to safeguard your personal data. Only authorized personnel have access to your data, and all relevant staff have signed confidentiality agreements. Any violations will be subject to legal penalties.When outsourcing services that involve personal data, we will strictly require contractors to uphold confidentiality obligations and implement necessary audits to ensure compliance.

04. External Links

This website may contain links to other websites. However, our privacy policy does not apply to those sites. You must refer to the privacy policy of each linked site.

05. Sharing Personal Data with Third Parties

This website will never provide, exchange, rent, or sell your personal data to any individuals, organizations, private companies, or public agencies unless required by law or contractual obligations.Exceptions include but are not limited to:

01. With your written consent

02. As required by law

03. To prevent danger to your life, body, freedom, or property

04. When cooperating with government agencies or academic institutions for statistical or research purposes in the public interest, and the data is processed in a way that makes individuals unidentifiable

05. When your behavior on the website violates our terms of service or causes harm to other users or third parties, and disclosure is necessary for identification, legal action, or contact

06. When it benefits your rights and interests

07. When we outsource vendors to collect, process, or use your data, and we will oversee them to ensure proper handling

06. Use of Cookies

To provide you with the best service, this website will place and access cookies on your device. You may set your browser’s privacy settings to high to refuse cookies, but doing so may cause some website features to function improperly.

07. Amendments to the Privacy Policy

This website’s privacy policy may be revised at any time to meet changing needs. All updates will be posted on this site.