Certification

Lab & Equipment

Process Control

Quality Culture

Partnership

World-Class Quality Management System

Key performance metrics tracked in real time: Customer Satisfaction, Reject Rate (<0.01%), Scratch Rate (<0.005%) and HSF compliance

Quality Control Design

Our engineering expertise allows us to build inspection systems that are simple, effective, and scalable — knowing what, when, and how to inspect to achieve optimal quality performance and cost efficiency.

ISO 9001 : 2015

Embedded within our ISO 9001:2015 quality management system, we integrate process development, manufacturing management, inspection, calibration, numerical analysis, nonconformity handling, and lessons learned into a unified platform. Automated Closed-Loop Corrective Action (CLCA) workflows ensure real-time alerts, root-cause analysis, and continuous, cross-functional improvement.

下载

ISO 13485 - Medical Devices

Certified in developing and manufacturing precision medical device and components.

This certification ensures that every stage — from design and development to production and traceability — complies with stringent global regulatory standards, helping customers streamline audits and reduce compliance risks.

AS9100 - Aerospace and Defense Industries

We meet the world’s most demanding aerospace and defense standards through precision machining, full traceability, and disciplined process control — ensuring every component performs with reliability and consistency.

Other Certifications

ISO 27001

Information Security

ISO 45001

Occupational Health & Safety

IATF 16949

Automotive

ISO 14001

Environment

ISO 27001

Information Security

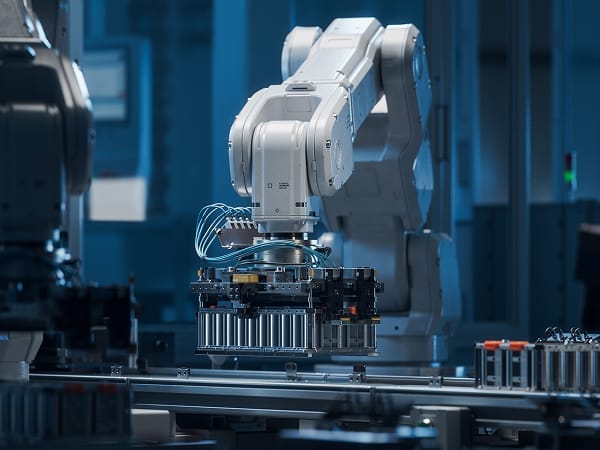

Inspection & Testing Laboratories

From defect detection to process innovation, our advanced inspection systems empower Catcher to deliver flawless precision — faster, smarter, and more reliably.

Dimensional Metrology

Coordinate-Measuring Machines (CMM) and optical/vision systems for ±1 µm accuracy

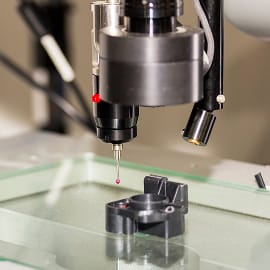

Contact Measurement Machine

Measures product dimensions using a contact probe, suitable for high-precision geometric inspection.

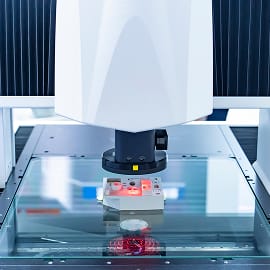

Vision Comparison Measuring System

Captures images to measure product dimensions; allows direct, rapid dimension marking and comparison with original CAD drawings.

Optical Measurement Machine

Utilizes non-contact optical measurement with high-precision linear scales, probes, and controllers to ensure measurement accuracy and system stability.

Cosmetic Inspection

Hardness testers, cross-hatch adhesion, gloss/chromaticity and surface-roughness measurement

Colorimeter

Measures color parameters (L, a, b) of materials for color deviation detection and color difference analysis.

Scanning Electron Microscope (SEM)

Uses a focused electron beam to scan the sample surface, producing high-magnification images via secondary or backscattered electrons. Allows on-image distance measurement and digital imaging. When combined with EDS (Energy Dispersive X-ray Spectroscopy), elemental analysis is also possible.

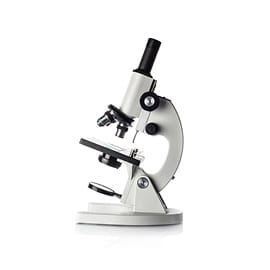

Optical Microscope

Uses visible light and optical lenses to magnify sample surfaces. Equipped with imaging software and digital cameras for on-screen measurements and image capture.

Surface Treatment Reliability Lab

ICP-OES, GC-MS, XRF and UV-Vis spectrometry to verify alloy composition and coating integrity

ICP-OES

Uses plasma to excite elements in the sample, causing them to emit light at characteristic wavelengths. The emitted light is then dispersed by an optical system, allowing for qualitative and quantitative analysis based on each element’s unique spectral lines.

GC-MS

Separates mixtures through gas chromatography, then analyzes the vaporized components with mass spectrometry to obtain molecular structure information.

UV-Vis

Employs ultraviolet or visible light lamps as a light source; through filters and dispersion, a specific single wavelength is directed onto the sample. By comparing the light energy absorption to a standard sample, the concentration of the analyte is determined.

XRF

Irradiates the sample with X-rays, causing inner-shell electrons of elements to absorb energy and emit characteristic X-rays as they return to the ground state. Different elements emit distinct X-ray signatures, enabling comprehensive elemental analysis of the sample.

FTIR

Infrared spectroscopy identifies materials based on how their molecules absorb infrared light at different wavelengths. FTIR uses mathematical conversion to transform raw interferograms into standard absorption spectra, allowing accurate analysis of material composition.

Statistical Process Control & Traceability

Data-driven oversight for consistent, predictable output

Real-Time SPC

Real-time Statistical Process Control (SPC) for key processes leverages measurement databases to monitor stability and variation, while advanced AI technologies extend this capability from product monitoring to proactive process parameter control.

Full Lot-Level Traceability

Our traceability system links raw materials to final shipment, recording every process parameter and inspection record. This transparency supports real-time analysis and continuous quality enhancement.

Relentless About Quality

We embed quality into every action — eliminating risk, elevating standards, and driving trust across everything we make.

Continuous Improvement

Beyond CLCA for nonconformities, we apply the PDCA cycle to manage risks and drive continuous improvement across all processes.

Turning Insight into Action

We review KPIs, feedback, and audit results weekly to turn insights into rapid improvement actions.

Quality Awareness Training

We train our teams on quality improvement tools and methods with our structured curriculum, and support growth through ASQ CQE and CSSBB certifications.

Partnering for Perfection

We view every customer as a co-engineer — uniting expertise and precision to achieve uncompromising quality.

Joint Quality Reviews & Audits

We work closely with customers to align our quality management system with their product specifications, regularly monitor progress toward their quality goals, and proactively propose optimization plans.

Certified Supplier Network

Every critical sub-supplier follows our rigorous onboarding standards and undergoes monthly quality performance reviews.

Start Your Project With Us

Feel free to contact Catcher Technology through the information below. We will respond to your inquiry as soon as possible.

联络我们

其他核心能力

站内搜寻

Start typing keywords to discover the service, support, or details you’re looking for.

隐私权政策

欢迎来到「可成网站」(以下称「本网站」)。为了让您安心使用本网站的各项服务与资讯,特此向您说明本网站的隐私权政策,以保障您的权益,请详阅下列内容:

01. 隐私权政策适用范围

本政策适用于您使用本网站服务时所涉及的个人资料搜集、处理与利用方式。但不适用于本网站所连结之其他网站,也不适用于非本网站所委托或管理之人员。

02. 个人资料的搜集、处理与利用方式

当您造访或使用本网站服务时,可能依服务性质请您提供必要的个人资料,且仅于特定目的范围内处理与利用,未经您的书面同意,不会另作他用。 使用如联络表单、留言或问卷等互动功能时,本网站可能会保留您的姓名、电子邮件、联络方式及使用时间。一般浏览时,伺服器会自动记录您的 IP 位址、使用时间、浏览器类型、浏览纪录等资讯,作为改善网站服务之用,不对外揭露。 为提供更精准的服务,本网站可能对问卷内容进行统计分析,统计结果可能以数据或文字呈现供内部研究或对外公开,但不包含个人身分资讯。

03. 资料保护

本网站的伺服器均设有防火墙、防毒系统及其他相关资安设备,以确保您的个人资料受到妥善保护。仅限经授权人员得以接触资料,所有相关人员皆已签署保密协议,违者将依法处理。 如因业务需要委外处理个人资料,本网站将充分监督并要求其确实遵守保密义务。

04. 外部连结

本网站可能提供外部网站连结,但本网站的隐私权政策并不适用于该等网站。请您自行参阅各该网站的隐私权政策。

05. 个人资料之第三方共享

本网站绝不会出售、交换、出租或提供您的个人资料予任何个人、公司或机关,但符合法律或契约义务之情形除外。

例外情形包括但不限于:

01. 经您书面同意

02. 法律明文规定

03. 为防止危及您的生命、身体、自由、财产之危险

04. 为公共利益,与政府或学术机构合作进行统计或学术研究(资料经处理后无法识别个人)

05. 您在本网站之行为违反服务条款,或造成其他使用者或第三人损害

06. 为维护您的权益

07. 委外机构协助搜集、处理或利用个人资料,且本网站依法监督其行为

06. Cookie 之使用

为提供更佳服务,本网站将于您的装置上写入并读取 Cookie。若您不愿接受,可透过浏览器设定提高隐私权等级,但可能导致部分功能无法正常运作。

07. 隐私权政策修订

本政策将因应需求随时修订,修改后的条款将公布于本网站。