Waste Management

In 2024, Catcher Group generated a total of 74,273.68 metric tons of waste, consisting of 0.52% hazardous business waste and 99.48% general business waste. The Company integrates resource conservation and efficiency into process development and product design, with the dual objectives of reducing raw material consumption and saving energy. To further strengthen circular economy practices, Catcher also develops and optimizes proprietary resource utilization technologies to enhance recycling performance.

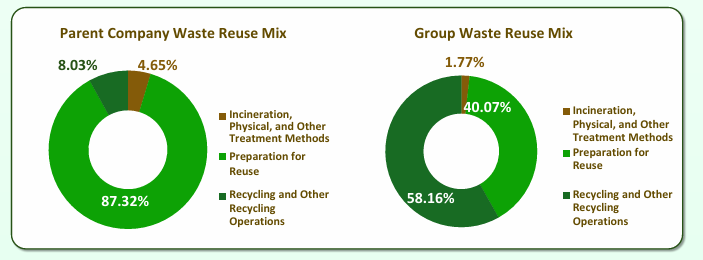

In compliance with local regulations and through the application of available technologies, waste is transported off-site for treatment, including preparation for reuse, recycling, and other recovery operations, thereby maximizing resource efficiency. As a result, the Parent Company achieved a waste reuse rate of 95.35%, while the Group’s reuse rate reached 98.23%. Waste intensity was recorded at 4.11 metric tons per NT$1 million of revenue. Looking ahead, Catcher remains committed to improving its waste reuse performance and advancing resource circularity across the Group.